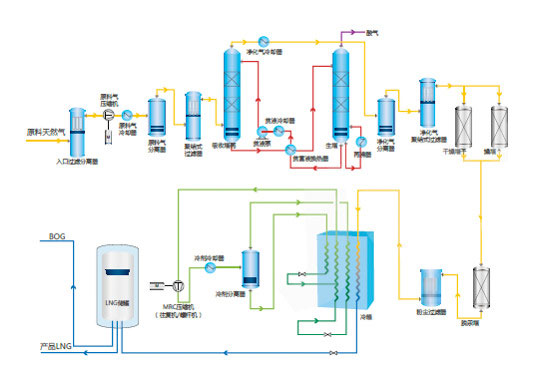

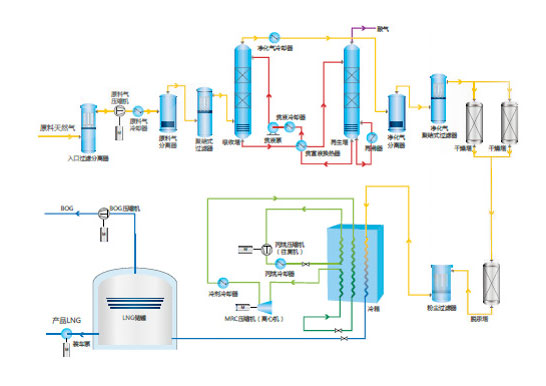

Natural gas liquefaction, Jereh has many experience of expansion refrigeration liquefaction process and mixed refrigeration liquefaction process. Especially, Jereh has developed and optimized single-stage mixed refrigeration(SMR), propane pre-cooling mixed refrigeration(C3-MR) and two-stage mixed refrigeration(DMR) processes for different needs.